Overview of our history

Competence, Commitment, Efficiency, Meticulousness

- 1946``ETABLISSEMENTS FEIN`` founded by Mr Paul FEIN

- 1968Company management taken over by Mr Henry FEIN, the founder's son

- 1994Moved to the current premises (1,000 m² in DANNEMARIE SUR CRÊTE)

- 1998Gained ISO 9001 certification

- 2002Gained ISO 16949 certification

- 2006Company taken over by Mr Sylvain PIERRON

- 2015Buildings extended to 3,000 m²

- 2017Workforce reached 25 people

A story of competence

- 1

Expertise : forming of all types of metals, as well as heat and chemical finishing treatments.

- 2

Responsiveness : optimisation of the production flows based on customer specifications and organisation of short logistics flows with local suppliers and subcontractors.

- 3

Know-how : experience and a meticulous approach to the design of tools for complex parts.

- 4

High level of quality enabling us to bid for contracts on the international market in a wide variety of industries : luxury goods, engineering industry, high and low voltage connectors, parts and components for use in the aerospace sector, the nuclear and automotive industries, magnetic components, electric motors, etc.

- 5

Constant reflection and a determination to provide solutions to our customers’ expectations through a process of continuous improvement and to give the finished product the best possible technical value.

- 6

The spirit of an SME in the management of human resources, placing the emphasis on knowledge, sharing skills and improving working conditions.

A story of commitment

- 1To effectiveness in supplying parts that meet customers' requirements

- 2To efficiency in manufacturing processes in order to optimise costs and production times

- Optimising automatic blanking and stamping production capacities

- Increasing secondary operation production capacities

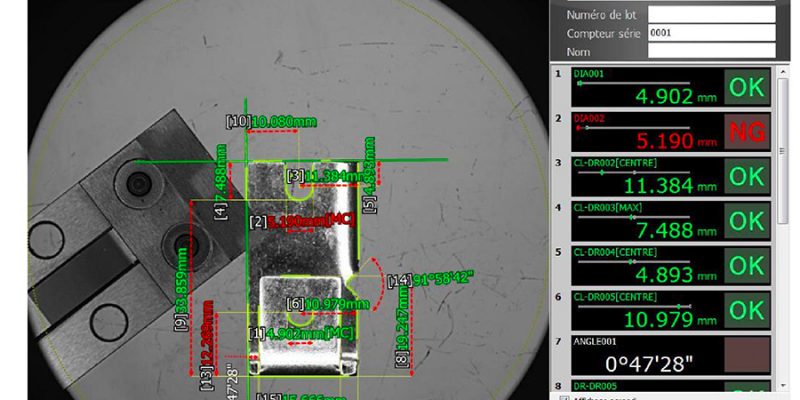

- Improving inspection and metrology capacities

- Reinforcing the level of customer satisfaction by providing useful and customised services

A story of efficiency

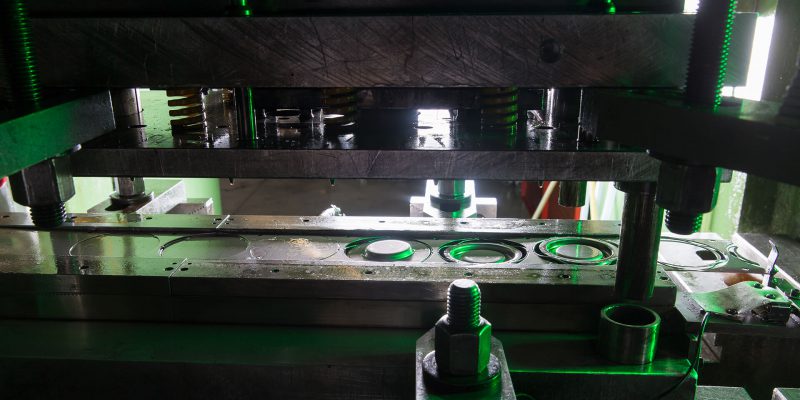

A large and varied stock of machines enables us to efficiently meet our customers’ requirements.

- 25 blanking presses, from 15 to 250 tonnes, using different technologies:

– gap frame,

– straight side,

– high speed,

– single and double-action hydraulic,

– pneumatic,

– manual

- Automatic tapping machines

- Spot welding

- Several manual and semi-automatic assembly stations

- Laser cutting

- 25 blanking presses, from 15 to 250 tonnes, using different technologies:

– gap frame,

– straight side,

– high speed,

– single and double-action hydraulic,

– pneumatic,

– manual

- Automatic tapping machines

- Spot welding

- Several manual and semi-automatic assembly stations

- Laser cutting

Competence Commitment Efficiency Meticulousness